Industrial Warehouse 1

Overview

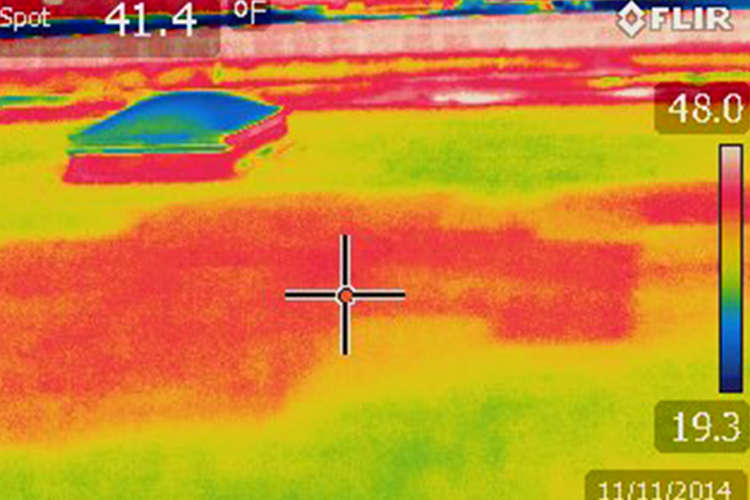

Diagnosis: Infrared scans were conducted at the site. Infrared photos show the wet areas, and are typically easily identified by the outline of the insulation boards that are wet. The areas were marked, and verified using core samples and moisture meter detection through the membrane.

Total roof area for Roof A – 42,000 sf

Total wet area for Roof A – 8,327 sf

During the final walk through after the scan, J Reynolds & Co., Inc. superintendent noticed some pitting on the metal deck under the wet areas. The areas were rusted through and the decking needed to be replaced.

Solution:

TPO Recover

- Remove all gravel, base flashings, coping and edge metal from the existing roof sections

- Mechanically attach specified insulation and TPO Rhino Bond roof assembly to the correctly prepared substrate

Flashing and Sheet Metal

- Install all new 24 gauge metal to all roof edges, mechanical units, and roof penetrations, utilizing coated metal as needed

Miscellaneous

- Provide complete submittal documents, including detailed drawings of the roof plan, roof system details, product data on all material used, along with current Material Safety Data Sheets for all products used in the re-roofing operations

- Includes equipment, materials and labor required for complete re-roofing operation

- All safety equipment/barricades required for both pedestrians and street traffic is included

- All work is per current NRCA, and Carlisle Specification Guidelines

- Provide Mechanical or Electrical Disconnect and Reconnect as required

- Add 2 additional drains

- Provide Manufacturer’s NDL Warranty, covering both materials and workmanship

- Provide Contractor Warranty, covering both materials and workmanship

Roof Repair: Existing Other Areas

Extensive repairs to extend the life of areas not replaced in 2014

- After making necessary preparations, Seal 20 roof vents with elastomeric coating

- Remove approximately 2600 lf of existing coping cap for reuse

- Completely remove approximately 2600 lf of modified base flashings from walls, roof dividers and expansion joints, spud the existing gravel surfacing a minimum of 8” into the field of the roof

- Prime areas, and heat apply one smooth ply, and one granular surfaced cap ply to all areas

- Install cold adhesive emultion to bottom of termination of all new flashing and re-embed gravel

- Replace three deteriorated pitch pockets and install new UV shields to six additional pitch pockets

- Remove approximately 400 lf of deteriorated or missing sealant from the top to the metal counter flashing and replace with new sealant

- Re-install removed coping using larger diameter fasteners to ensure proper attachment